What material makes the PET preform mould better?

2023-12-15

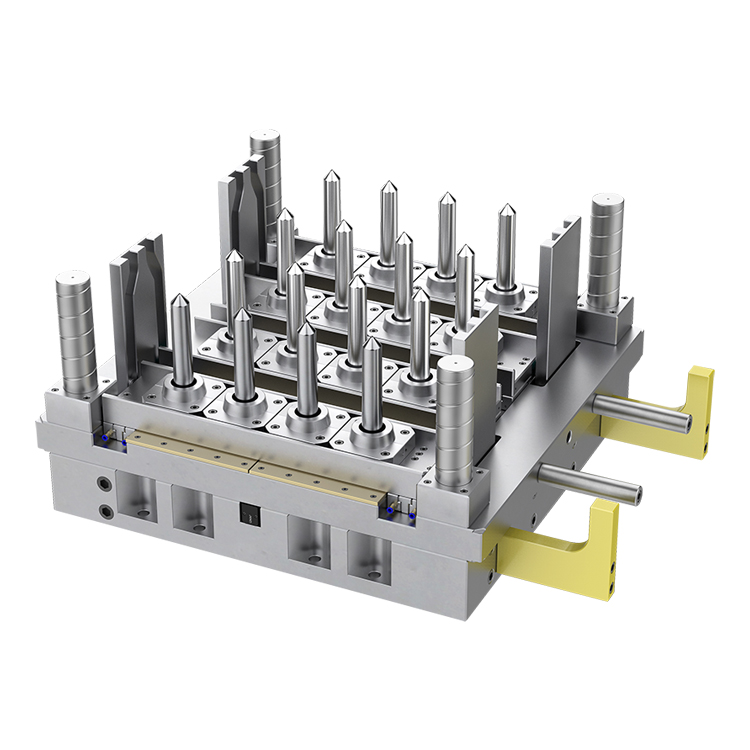

PET (Polyethylene terephthalate) preform molds are used in the production of PET bottles and containers through a process called injection molding. The choice of material for PET preform molds is crucial for ensuring durability, precision, and longevity of the molds. Some materials commonly used to make PET preform molds include:

1. Tool Steel: Tool steels like P20, H13, or S136 are widely used for PET preform molds. These steels offer good hardness, wear resistance, and machinability. H13 steel, for example, is known for its excellent heat resistance and toughness, making it suitable for high-temperature applications like injection molding.

2. Stainless Steel: Certain grades of stainless steel (such as 420 or 316 stainless steel) are used in PET preform molds. Stainless steel offers corrosion resistance, good surface finish, and can withstand high molding pressures and temperatures.

3. Aluminum: Aluminum alloys, particularly 7000 series aluminum, are sometimes used for PET preform molds, especially for shorter production runs or prototypes. Aluminum molds offer good thermal conductivity, which can aid in faster cooling cycles, but they may not be as durable as steel molds for high-volume production.

4. Beryllium Copper: This material is known for its excellent thermal conductivity, which can aid in efficient cooling of the mold, leading to faster cycle times. Beryllium copper molds are used for certain high-speed injection molding applications.

The choice of material for PET preform molds depends on various factors such as production volume, required precision, cost considerations, expected tool life, and the specific requirements of the molding process. Tool steel is a popular choice due to its balance of durability, hardness, and suitability for high-volume production, but other materials may be suitable depending on the application and production needs.