Innovations in Square Nuts: New Materials and Modern Applications

2024-07-24

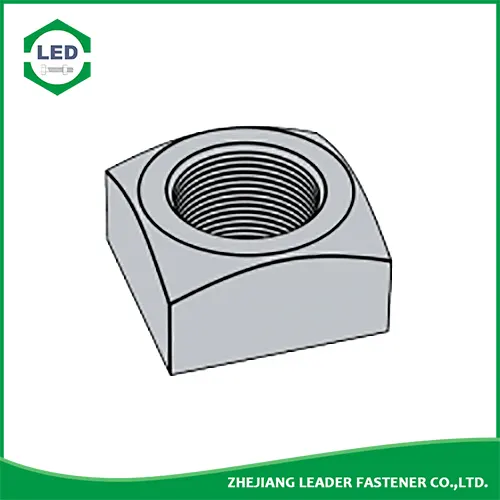

Square nuts have been a staple in construction and mechanical applications for centuries. Despite their long history, innovations in materials and design continue to enhance their functionality and expand their use in modern applications. In this blog, we will explore the latest innovations in square nuts, focusing on new materials and contemporary uses.

The Evolution of Square Nuts

Traditionally, square nuts were made from basic steel or iron. However, advancements in materials science and manufacturing techniques have led to the development of square nuts with enhanced properties, making them suitable for a broader range of applications.

Innovative Materials in Square Nuts

1. Titanium Square Nuts: Titanium offers a combination of strength, lightweight, and corrosion resistance, making it ideal for aerospace, marine, and medical applications. Titanium square nuts are used in environments where weight savings are crucial without compromising on strength.

2. Composite Square Nuts: Made from high-performance composite materials, these square nuts offer excellent strength-to-weight ratios and are resistant to chemicals and extreme temperatures. They are used in industries such as automotive, aerospace, and defense.

3. Nylon Square Nuts: Nylon square nuts are non-metallic and offer excellent resistance to corrosion, chemicals, and moisture. They are ideal for electrical applications where non-conductivity is essential, as well as for use in environments where metal nuts might corrode or degrade.

Modern Applications of Square Nuts

1. Renewable Energy: In the renewable energy sector, particularly in wind and solar power installations, square nuts are used for their durability and resistance to loosening under vibrations. They ensure the stability and longevity of these installations in harsh environments.

2. 3D Printing and Prototyping: Square nuts are used in 3D printing to secure components and in prototyping to quickly assemble and disassemble parts. Their ease of use and reusability make them ideal for iterative design processes.

3. Robotics and Automation: In robotics, square nuts are used for assembling frames and securing components. Their resistance to loosening and ease of installation make them suitable for dynamic environments where precision and stability are required.

4. Architectural Applications: Square nuts are increasingly used in architectural applications for their aesthetic appeal and functional benefits. They are used in visible joints and connections where their unique shape can add to the design elements.

Advantages of New Materials

1. Enhanced Durability: Modern materials such as titanium and composites significantly increase the durability and lifespan of square nuts, making them suitable for extreme environments.

2. Weight Reduction: Innovations in materials have led to the development of lightweight square nuts that do not compromise on strength, essential for applications where weight savings are critical.

3. Corrosion Resistance: New materials like nylon and coated metals provide superior resistance to corrosion, extending the life of the fasteners in harsh conditions.

4. Chemical Resistance: Composite and nylon square nuts offer excellent resistance to a wide range of chemicals, making them suitable for use in chemical processing and handling applications.

Conclusion

The evolution of square nuts continues with innovations in materials and modern applications. From aerospace to renewable energy, these advancements are expanding the utility and functionality of square nuts in various industries. Understanding these innovations can help you select the right square nut for your specific needs, ensuring durability, stability, and performance in your projects.